Introduction:

In today's fast-paced manufacturing industry, businesses are constantly seeking innovative solutions to meet the ever-increasing demands of their customers. One such solution that has gained significant popularity is aluminum prototype manufacturing. With its excellent strength-to-weight ratio and versatility, aluminum has become the go-to material for numerous industries. This blog explores the intricate world of aluminum prototype manufacturing in the Bay Area, focusing on its benefits, applications, and the top CNC machine shops providing precision aluminum prototypes.

The Rise of Aluminum Prototyping:

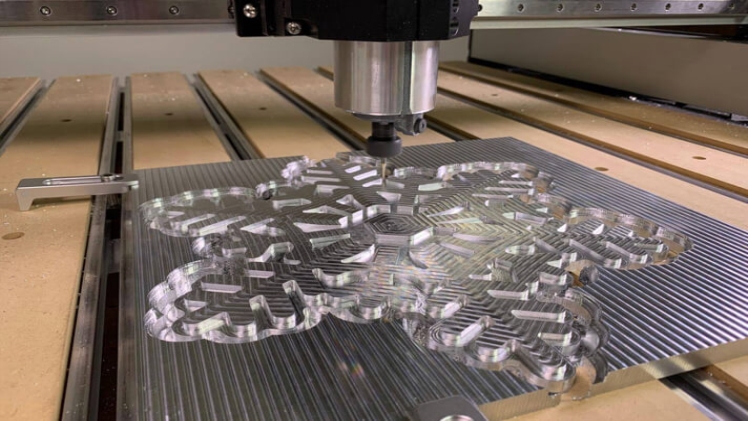

The advancement of computer numerical control (CNC) machining technology has revolutionized the way prototypes are developed. Prototyping with aluminum offers unmatched precision, durability, and cost-effectiveness. Unlike other materials, aluminum prototypes can be manufactured quickly and accurately, allowing businesses to iterate and refine their designs faster than ever before.

Benefits of Aluminum Prototypes:

1. Lightweight and Strong: Aluminum's lightweight nature makes it ideal for aerospace, automotive, and electronic industries. It offers remarkable strength with the ability to withstand the rigors of real-world applications.

2. Excellent Machinability: Aluminum is known for its high machinability, which means it can be easily manipulated and modified during the prototyping process. Its workability allows for intricate designs and precise detailing.

3. Cost-effective Production: Aluminum prototypes are relatively affordable to manufacture when compared to other metals. Simultaneously, their durability eliminates the need for frequent replacements, resulting in long-term cost savings.

4. Enhanced Thermal Conductivity: Aluminum prototypes excel in conducting thermal energy, making them suitable for heat exchange applications and electronic housings that require efficient cooling.

5. Versatile Surface Finishing Options: Aluminum prototypes can be finished through various methods like anodizing, powder coating, or painting, enabling designers to bring their creative visions to life.

Applications of Aluminum Prototypes:

1. Aerospace Industry: Lightweight and strong aluminum prototypes are extensively used in the aerospace sector for components like brackets, engine parts, and structural frameworks.

2. Automotive Industry: Aluminum prototypes find applications in the automotive industry, particularly for lightweight structural parts like engine blocks, transmissions, and suspensions.

3. Electronics Industry: Given its thermal conductivity properties, aluminum prototypes are utilized in creating heat sinks and electronic enclosures, essential for dissipating excess heat generated by electronic components.

4. Medical Industry: Aluminum prototypes are used in medical devices and equipment, such as surgical tools, imaging equipment, and prosthetic limbs, to deliver reliability and strength.

Top CNC Machine Shops in the Bay Area:

1. CNC Machines Shop A:

Offering precision machining services, this shop specializes in manufacturing aluminum prototypes of exceptional quality. Their state-of-the-art CNC machines ensure accuracy and efficiency for even the most complex designs.

2. CNC Machines Shop B:

Known for their expertise in aluminum prototype manufacturing, this shop consistently delivers top-notch products. With their extensive knowledge of CNC machining, they can tackle intricate designs with ease.

3. CNC Machines Shop C:

Backed by years of experience, this shop has earned a reputation for providing aluminum prototypes of superior quality. Their dedication to precision and customer satisfaction has made them a preferred choice in the Bay Area.

4. CNC Machines Shop D:

With a focus on aluminum prototype manufacturing, this shop combines cutting-edge technology and skilled craftsmanship to produce highly accurate prototypes. Their commitment to delivering on time is commendable.

Conclusion:

Aluminum prototype manufacturing has significantly transformed the way businesses approach product development. Its lightweight properties, excellent machinability, and cost-effectiveness make it an invaluable material for a wide array of industries. The top CNC machine shops in the Bay Area excel in aluminum prototype manufacturing, offering precise and high-quality products. By leveraging the benefits of aluminum prototypes, businesses can bring their innovative ideas to life while minimizing costs and maximizing efficiency.