Aluminum is a favorite material for CNC machining thanks to its versatility, workability, and strength. From aerospace to automotive, medical to consumer products, this lightweight and affordable metal has become the go-to choice for many businesses that want to create high-quality and long-lasting products.

In this article, we will take a comprehensive look at aluminum CNC machining, its benefits, and how it is commonly used to create parts such as aluminum CNC machining knobs.

What is Aluminum CNC Machining?

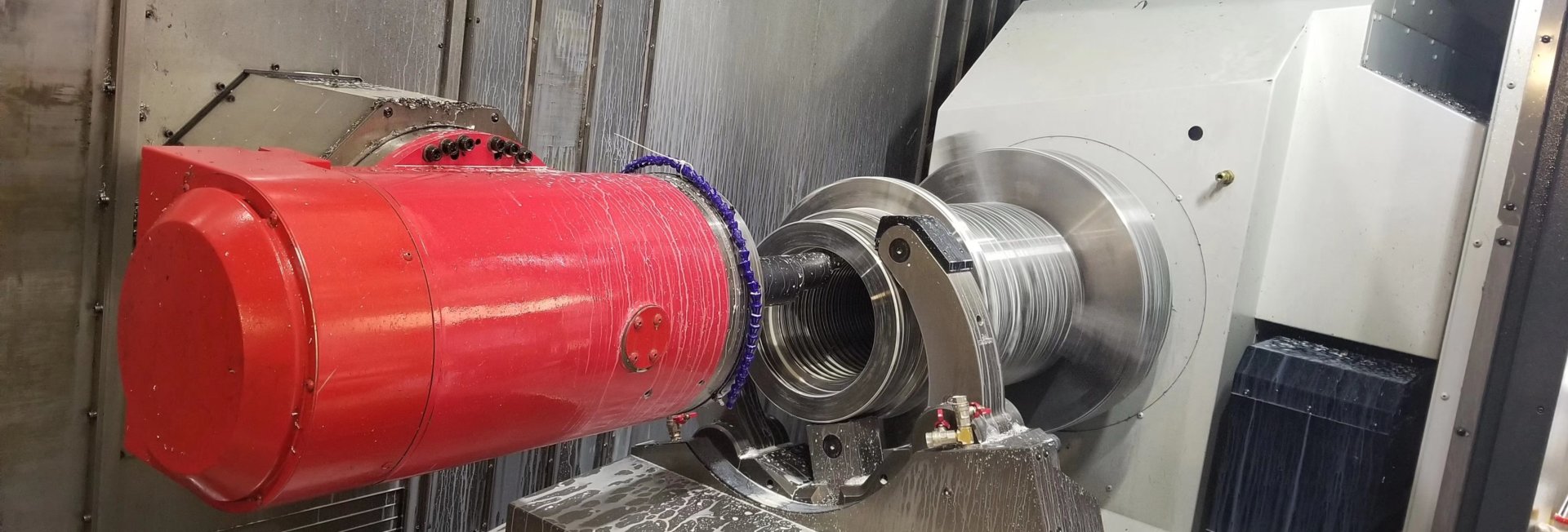

CNC machining is a process that uses computer-controlled machines to automatically cut, shape, and drill different materials into the desired shape or form. Aluminum CNC machining, therefore, is the process of using computer-controlled machines to shape aluminum into the required form or shape.

The use of CNC machines is highly beneficial compared to traditional machining methods because it is more precise, faster, and more efficient. CNC machines are programmed to perform specific tasks, which means that once programmed, they can reproduce the same part multiple times with the same level of accuracy.

Benefits of Aluminum CNC Machining

1. Versatility: Aluminum is a highly versatile material that can be molded into various shapes and used for different applications.

2. Lightweight and Durable: Aluminum is lightweight yet strong, making it a popular metal of choice for manufacturing products that require high strength-to-weight ratios.

3. Cost-Effective: Aluminum is relatively inexpensive compared to other metals, making it an affordable choice for creating prototypes and mass production.

4. Precision: CNC machining offers exceptional precision and accuracy, perfect for producing complex shapes and parts that require high levels of detail.

5. Speed: CNC machines operate at high speeds, meaning that parts can be produced quickly without compromising on precision or quality.

How is Aluminum CNC Machining used to manufacture Knobs?

Aluminum CNC machining is commonly used to create knobs used in various applications. These knobs are used in cars, electronics, aerospace, medical equipment, and many other industries. Through CNC machining, it is possible to create custom knobs that fit specific designs or specifications.

The different steps involved in CNC machining knobs include:

1. Design: Creating a design that meets the customer's specifications or needs.

2. Programming: Creating a CNC program that specifies the toolpaths and tooling needed to create the desired part.

3. Blank Preparation: Starting with a block of aluminum, preparing surfaces for cutting, and drilling holes.

4. Machining: CNC milling the aluminum block into the desired shape.

5. Finishing: Polishing, deburring, and adding coatings, according to customer requirements.

Why choose Aluminum CNC Machining for your Knobs?

Aluminum CNC machining provides an accurate and affordable method for producing custom knobs of the highest quality. Some of the benefits of using aluminum for your knobs include:

1. Lightweight yet durable: Aluminum is lightweight yet strong, making it ideal for manufacturing knobs that require high strength-to-weight ratios.

2. Machinability: Aluminum is easy to machine and work with, which makes CNC machining of aluminum effective and efficient.

3. Corrosion resistance: Aluminum is naturally corrosion-resistant, which makes it suitable for manufacturing products in corrosive environments.

4. Versatility: Aluminum can be easily molded into various shapes and designs, making it ideal for manufacturing custom knobs.

In conclusion, Aluminum CNC machining is a highly beneficial and versatile process that enables the production of high-quality parts, including aluminum CNC machining knobs, quickly and cost-effectively. Its precision, speed, and versatility have made it the go-to material of choice for many businesses looking for high-quality and long-lasting products, and we believe that it will continue to be a popular choice in the years to come.